Solder Earring Back Flame Torch Turned Dark What Dip Get Shiny Again Forum

I enamel on various metals making a diverseness of pieces from mail service earrings to 5″ x 8″ framed enamels. The enameling techniques I use for sterling silver are cloisonné, champlevé and plique-à-jour. When I began enameling in 1971, it was accepted that true transparent enamels could not exist used on sterling silver. Later studying with Joanna Stone, I persevered with my experimentation until I developed a process for enameling on sterling silver. Every step is of import.

|

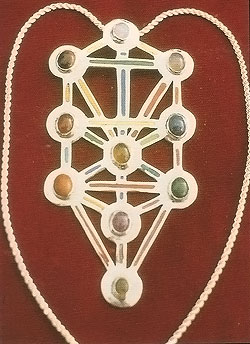

| Tree of Life: Meditation necklace. 3″ x 6″ champlevé sterling, fine silver, opaque enamel. |

My sterling enamel jewelry pieces are made with a narrow sterling frame that I cut out with a jeweler'south saw bract. The same design is used to cutting out both the bottom piece and the frame. The frame is sweat soldered to the face of the sterling piece that is to be enameled. This method eliminates the need for making a bezel setting for the enamel. I also use this method for combining champlevé with the cloisonné. Instead of making just a frame, I saw out ii full size pieces and then saw out cells in which I will enamel and place cloisonné wires in either some or all of the cells.

The sterling silver needs to be accurately assimilated of no less than 92/100 silvery content. Reputable refiners can do this. I specify that the sterling is to exist enameled and, if possible, the sheets are to exist annealed. When I use 24 ga for the enameled piece, I select xviii ga for the frame. With an enamel piece of 18 ga, I utilize twenty ga to 22 ga for the frame. The eighteen ga base of operations needs only ane counter enamel coat. Since the thinner gauge volition warp easily, information technology needs nigh three coats of counter.

I often do an exact drawing using colored pencils. From the drawing, I make templates of twenty ga to 22 ga copper equally patterns for the enamel piece and the frame. I use the jeweler'due south saw to cut these templates; then I scribe their shapes on the sterling sheet and saw them out. If the sterling is not annealed, I coat both sides of the ii pieces with soldering flux (borax and water, or Battern'southward) and anneal them either with a torch or in the kiln. The flux and oxide are removed in a fresh hot pickle of 1:one nitric solution.

Caution!

Remember to add together acrid to water. Never add together h2o to acrid. When using acrid, it is advisable to wear proper gloves, long sleeves, face mask and safety goggles. Sparex may be substituted for the nitric solution. If the sterling canvas came annealed, then it only needs to soak briefly in the fresh acid solution to remove all oils. To neutralize the piclde, I add together water to the solution followed by the very slow addition of small quantities of blistering soda. I wash the pieces thoroughly with fresh water.

Next, I borax-flux the piece and the frame and then secure them together with binding wire to be sweat soldered with Information technology silver solder or tested difficult silverish solder if I am unable to get the IT solder. There should exist no solder on the area of the metal to be enameled. I bright dip the soldered unit to remove oxides. A freshly made 1:1 nitric acid solution at room temperature is needed for the bright dip. Sparex 2 as well works well. Brilliant dipping is the most of import stride in the preparation of sterling for transparent enamels. The vivid dip eats away a layer of sterling silver oxide, along with a layer of sterling silver.

The trick is to know when to remove the piece from the acid before irreparable damage is done by extreme acid pitting. This depletion gilding is learned with experience. The soldered piece is placed gently in the acrid bathroom. I use a Pyrex dish with a cover for the acid. Bubbles that rise to the surface of the metal are removed periodically past brushing beyond the piece with a long feather. When the piece is very dark, compatible gray in well-nigh places (it will be darkest around the solder seam), it is removed from the vivid dip bath with wooden or plastic tongs, rinsed, neutralized with baking soda, rinsed and cleaned with a drinking glass brush.

I put on prophylactic gloves to protect my peel from the minute glass threads that pause off and can stick tenaciously and painfully. I rub the metallic lightly with a glass brush in a circular movement under running water to minimize breakage of the glass castor. The drinking glass castor removes the blackness residuum of oxide that the acid brought to the surface.

At this point, the piece may exist domed evenly and slightly with a rawhide mallet by hit the face of the piece that is held over a steel stake. The findings are soldered on the back with as petty It solder as possible, the firescale removed once more and the piece glass-brushed every bit before. The slice is at present ready to be enameled.

I use 80 mesh, transparent, unleaded enamels. I also buy these enamels in lump form that I grind with a mortar and pestle when I am gear up to use them. I prefer grinding my own. I wash the enamels, well-nigh a tablespoon of each ground colour, with distilled water until the water is clear. To make the enamels absolutely clean, a few drops of nitric acid are added to a pint of water and the enamels are then re-washed in this solution. A concluding washing with clean water is required to rinse away the acid h2o. I have found that unused moisture enamel powder tends to pause down and become discolored if stored.

The first coat of enamel is hard fusing to prevent that coat from bubbling through subsequent coats of medium and soft fusing enamel. I wet pack damp enamels with thin to medium size horsehair brushes. I also use a curved dental tool, the double-concluded stainless steel kind that has one end shaped like a little scoop. The frame, of course, is not enameled. I moisture pack the back get-go, add a few drops of uncut Klyr-Fyre on the enamel and then draw off any of the backlog water with a slice of tissue.

When the enamel has partially dried or become tacky, the piece is turned over to enamel the front side. There I wet pack Thompson's argent flux #757, especially if I plan to use transparent reds or pinks; otherwise, I sometimes wet pack the transparents as the base of operations coat. Though leaded enamels yield ameliorate colors in the reds, I experience safer staying with the unleaded enamels. The piece is placed on a trivet to dry and so fired merely to maturity in my 110V electrical kiln at nigh 1350°F. I employ a pyrometer, only my sixth sense tells me when to peep in the kiln.

Next comes placing of the cloisonné wires with uncut Klyr-Fyre. For gold wire, I hammer 22K, sixteen ga or 18 ga round wire into the rectangular thinness I want. The moisture packing, drying and firing is repeated three to 5 times until the fired enamel is slightly higher than the frame rim.

Finishing is washed by stoning under water, first with a coarse Carborundum stick so a medium-grain one. The grinding continues until all enamel is removed from the frame and the wires, leaving the enamel fifty-fifty. The dull enamel surface is thoroughly washed and glass-brushed to remove whatever grains of Carborundum. For a final finish there is a choice. The surface of the enamel may be rubbed with fine paste-wax polish on the fingertips for a matte finish, or the piece may be flash-fired in the kiln for a glossy surface.

If the slice is flash fired, the exposed sterling silver frame will need to accept the oxidation removed. This removal is a delicate matter considering the enamel should not be scratched. I use tripoli or white diamond compound on a hard felt vitrify on a regular polishing motor. I strongly suggest that if you lot have not used a polishing motor that you lot either take a jewelry class or have someone knowledgeable show you lot how to use the equipment. You can be hurt badly if you are inexperienced or careless.

Intendance must exist taken non to overheat the slice with the polishing bike or else the enamel volition crack. If you remove the piece from the cycle when your fingers become hot, you lot will exist rubber. When the oxide has been buffed off, a soft flannel buff charged with rouge is used for a concluding polish of the sterling silver frame. If the piece is a pin, the pin stem is fastened to the findings that were soldered on earlier enameling. For small surfaces and getting into crevices with buffing wheels, I use the Dremel electric tool post-obit the same progression of buffing wheels with white diamond, tripoli and ruddy rouge.

For plique-à-jour earrings, I bend and hard solder sterling silverish 14 ga round wire in the shape of a fish or a bird and and then flatten the forms with hammers. Sometimes I solder on a spring ring before the depletion gilding. Sometimes I drill a hole for the earwire.

The sterling is prepared for enameling as previously described. After hot pickling and rinsing the frame, it is placed on a sheet of mica and then on the firing planche. The enamel will not adhere to the mica. The enamel is moisture packed with transparent enamels, dried and fired. This process is repeated until the fired enamel is at the edge of the rim of the frame. The piece is stoned gently nether running water until no enamel is on the frame. The slice is flash fired, and the sterling silver frame is polished later the mica sail is removed.

I have always had a small burn extinguisher in my studio, but, fortunately, I have never had to use it. One needs to respect and approach with caution acids, electrical equipment and other tools to be able to work safely.

P. Alexa Foley began enameling in 1971. She studied with Joanna Rock, and and then persevered with experimenting until she developed her method for enameling on sterling. She spent many years equally a successful enamelist, creating cloisonné, champlevé and plique-à-jour enamels. As a realtor with a GRI, she now resides in Maui, HI where she does some enameling and painting. In June 2001, Alexa received her Chiliad.A. in Cultural Anthropology and Transformative Learning.

bradleydeconsenry.blogspot.com

Source: https://www.ganoksin.com/article/enameling-on-sterling-silver/

0 Response to "Solder Earring Back Flame Torch Turned Dark What Dip Get Shiny Again Forum"

Post a Comment